CVV

Application and Description:

For supervisory electrical equipment, station control circuits, outdoor, suitable installation in dry or wet cable trenches.

Name Code:

C: For control

V: Vinyl

V: Vinyl

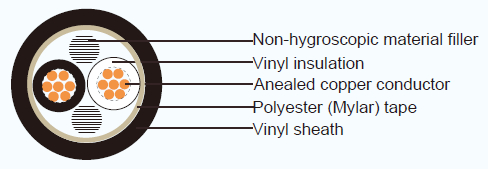

Cable Construction:

Conductor: Circular or compacted circuar stranded annealed copper wires

Seperator: A proper separator may be applied to a conductor

Insulation: Vinyl

Color :

2 cores- Black and white3 cores- Black, white and red

4 cores- Black, white, red and green

More than 4 cores: Black core with marking numbers

Filler: Non-hygroscopic material(optional) Binding tape: Polyester (Mylar) tape (optional) Sheath: Vinyl, Black color

Technical Characteristics:

Maximum conductor temperature 90oC

Circuit voltage not exceeding 600 volts

Test voltage 2000 volts

Cable Parameter:

| NO. OF CORES | NOMINAL SECTIONAL AREA | NO. OF WIRE | DIAMETER OF CONDUCTOR (APPROX.) | THICKNESS OF INSULATION | THICKNESS OF SHEATH |

OVERALL DIAMETER (APPROX.) | MAXIMUM DC. RESISTANCE OF CDR. AT 20°C |

CABLE WEIGHT (APPROX.) |

| MM^2 | MM | MM | MM | MM | OHM / KM | KG / KM | ||

| 2 | 1.25 | 7/0.45 | 1.35 | 0.8 | 1.5 | 9.4 | 16.8 | 100 |

| 2 | 7/0.6 | 1.8 | 0.8 | 1.5 | 10.5 | 9.42 | 130 | |

| 3.5 | 7/0.8 | 2.4 | 0.8 | 1.5 | 11.5 | 5.3 | 175 | |

| 5.5 | 7/1.0 | 3 | 1 | 1.5 | )3.5 | 3.4 | 245 | |

| 8 | 7/1.2 | 3.6 | 1.2 | 1.5 | 15.5 | 2.36 | 335 | |

| 8 | compacted | 3.4 | 1.2 | 1.5 | 2.34 | 325 | ||

| 14 | 7/1.6 | 4.8 | 1.4 | 1.5 | 19 | 1.33 | 520 | |

| 14 | compacted | 4.4 | 1.4 | 1.5 | 18 | 1.34 | 500 | |

| 22 | 7/2.0 | 6 | 1.6 | 1.6 | 23 | 0.84 | 760 | |

| 22 | compacted | 5.5 | 1.6 | 1.5 | 21 | 0.849 | 715 | |

| 3 | 1.25 | 7/0.45 | 1.35 | 0.8 | 1.5 | 9.9 | 16.8 | 120 |

| 2 | 71'0.6 | 1.8 | 0.8 | 1.5 | 11 | 9.42 | 160 | |

| 3.5 | 7/0.8 | 2.4 | 0.8 | 1.5 | 12.5 | 5.3 | 220 | |

| 5.5 | 7/1.0 | 3 | 1 | 1.5 | 14.5 | 3.4 | 320 | |

| 8 | 7/1.2 | 3.6 | 1.2 | 1.5 | 16.5 | 2.36 | 440 | |

| 8 | compacted | 3.4 | 1.2 | 1.5 | 16 | 2.34 | 425 | |

| 14 | 7/1.6 | 4.8 | 1.4 | 1.5 | 20 | 1.33 | 690 | |

| 14 | compacted | 4.4 | 1.4 | 1.5 | 19 | 1.34 | 665 | |

| 22 | 7/2.0 | 6 | 1.6 | 1.6 | 24 | 0.84 | 1020 | |

| 22 | compacted | 5.5 | 1.6 | 1.6 | 23 | 0.849 | 975 | |

| 4 | 1.25 | 71'0.45 | 1.35 | 0.8 | 1.5 | 11 | 16.8 | 145 |

| 2 | 7/0.6 | 1.8 | 0.8 | 1.5 | 12 | 9.42 | 195 | |

| 3.5 | 7/0.8 | 2.4 | 0.8 | 1.5 | 13.5 | 5.3 | 275 | |

| 5.5 | 7/1.0 | 3 | 1 | 1.5 | 16 | 3.4 | 400 | |

| 8 | 7/1.2 | 3.6 | 1.2 | 1.5 | 18 | 2.36 | 555 | |

| 8 | compacted | 3.4 | 1.2 | 1.5 | 17.5 | 2.34 | 535 | |

| 14 | 7/1.6 | 4.8 | 1.4 | 1.6 | 22 | 1.33 | 890 | |

| 14 | compacted | 4.4 | 1.4 | 1.5 | 2 1 | 1.34 | 855 | |

| 22 | 7/2.0 | 6 | 1.6 | 1.7 | 27 | 0.84 | 1320 | |

| 22 | compacted | 5.5 | 1.6 | 1.7 | 25 | 0.849 | 1260 | |

| 5 | 1.25 | 7/0.45 | 1.35 | 0.8 | 1.5 | 11.5 | 16.8 | 170 |

| 2 | 7/0.6 | 1.8 | 0.8 | 1.5 | 13 | 9.42 | 230 | |

| 3.5 | 71'0.8 | 2.4 | 0.8 | 1.5 | 14.5 | 5.3 | 330 | |

| 5.5 | 7/1.0 | 3 | 1 | 1.5 | 17 | 3.4 | 485 | |

| 8 | 7/1.2 | 3.6 | 1.2 | 1.5 | 20 | 2.36 | 675 | |

| 8 | compacted | 3.4 | 1.2 | 1.5 | 19.5 | 2.34 | 655 | |

| 14 | 7/1.6 | 4.8 | 1.4 | 1.6 | 25 | 1.33 | 1090 | |

| 14 | compacted | 4.4 | 1.4 | 1.6 | 24 | 1.34 | 1060 | |

| 6 | 1.25 | 7/0.45 | 1.35 | 0.8 | 1.5 | 12.5 | 16.8 | 200 |

| 2 | 7/0.6 | 1.8 | 0.8 | 1.5 | 14 | 9.42 | 270 | |

| 3.5 | 7/0.8 | 2.4 | 0.8 | 1.5 | 15.5 | 5.3 | 390 | |

| 5.5 | 7/1.0 | 3 | 1 | 1.5 | 18.5 | 3.4 | 570 | |

| 8 | 7/1.2 | 3.6 | 1.2 | 1.5 | 22 | 2.36 | 800 | |

| 8 | compacted | 3.4 | 1.2 | 1.5 | 21 | 2.34 | 775 | |

| 14 | 7/1.6 | 4.8 | 1.4 | 1.7 | 27 | 1.33 | 1310 | |

| 14 | compacted | 4.4 | 1.4 | 1.7 | 26 | 1.34 | 1270 | |

| 7 | 1.25 | 7/0.45 | 1.35 | 0.8 | 1.5 | 12.5 | 16.8 | 215 |

| 2 | 7/0.6 | 1.8 | 0.8 | 1.5 | 14 | 9.42 | 295 | |

| 3.5 | 7/0.8 | 2.4 | 0.8 | 1.5 | 15.5 | 5.3 | 425 | |

| 5.5 | 7/1.0 | 3 | 1 | 1.5 | 18.5 | 3.4 | 630 | |

| 8 | 7/1.2 | 3.6 | 1.2 | 1.5 | 22 | 2.36 | 885 | |

| 8 | compacted | 3.4 | 1.2 | 1.5 | 21 | 2.34 | 860 | |

| 8 | 1.25 | 7/0.45 | 1.35 | 0.8 | 1.5 | 13.5 | 16.8 | 240 |

| 2 | 7/0.6 | 1.8 | 0.8 | 1.5 | 15 | 9.42 | 335 | |

| 3.5 | 7/0.8 | 2.4 | 0.8 | 1.5 | 17 | 5.3 | 485 | |

| 5.5 | 7/1.0 | 3 | 1 | 1.5 | 20 | 3.4 | 720 | |

| 8 | 7/1.2 | 3.6 | 1.2 | 1.6 | 24 | 2.36 | 1030 | |

| 8 | compacted | 3.4 | 1.2 | 1.6 | 23 | 2.34 | 995 | |

| 10 | 1.25 | 7/0.45 | 1.35 | 0.8 | 1.5 | 15.5 | 16.8 | 305 |

| 2 | 7/0.6 | 1.8 | 0.8 | 1.5 | 17.5 | 9.42 | 425 | |

| 3.5 | 7/0.8 | 2.4 | 0.8 | 1.5 | 19.5 | 5.3 | 620 | |

| 5.5 | 7/1.0 | 3 | 1 | 1.6 | 24 | 3.4 | 930 | |

| 8 | 7/1.2 | 3.6 | 1.2 | 1.8 | 29 | 2.36 | 1340 | |

| 8 | compacted | 3.4 | 1.2 | 1.7 | 28 | 2.34 | 1290 | |

| 12 | 1.25 | 7/0.45 | 1.35 | 0.8 | 1.5 | 16 | 16.8 | 345 |

| 2 | 7/0.6 | 1.8 | 0.8 | 1.5 | 18 | 9.42 | 480 | |

| 3.5 | 7/0.8 | 2.4 | 0.8 | 1.5 | 21 | 5.3 | 705 | |

| 5.5 | 7/1.0 | 3 | 1 | 1.7 | 25 | 3.4 | 1080 | |

| 8 | 7/1.2 | 3.6 | 1.2 | 1.8 | 29 | 2.36 | 1540 | |

| 8 | compacted | 3.4 | 1.2 | 1.8 | 2.34 | 1490 | ||

| 15 | 1.25 | 7/0.45 | 1.35 | 0.8 | 1.5 | 17 | 16.8 | 405 |

| 2 | 7/0.6 | 1.8 | 0.8 | 1.5 | 19 | 9.42 | 575 | |

| 3.5 | 7/0.8 | 2.4 | 0.8 | 1.5 | 22 | 5.3 | 855 | |

| 5.5 | 7/1.0 | 3 | 1 | 1.7 | 27 | 3.4 | 1310 | |

| 20 | 1.25 | 7/0.45 | 1.35 | 0.8 | 1.5 | 19 | 16.8 | 515 |

| 2 | 7/0.6 | 1.8 | 0.8 | 1.5 | 22 | 9.42 | 735 | |

| 3.5 | 7/0.8 | 2.4 | 0.8 | 1.6 | 25 | 5.3 | 1120 | |

| 5.5 | 7/1.0 | 3 | 1 | 1.9 | 31 | 3.4 | 1720 | |

| 30 | 1.25 | 7/0.45 | 1.35 | 0.8 | L.6 | 23 | 16.8 | 750 |

| 2 | 7/0.6 | 1.8 | 0.8 | 1.7 | 26 | 9.42 | 1100 | |

| 3.5 | 7/0.8 | 2.4 | 0.8 | 1.8 | 30 | 5.3 | 1660 |